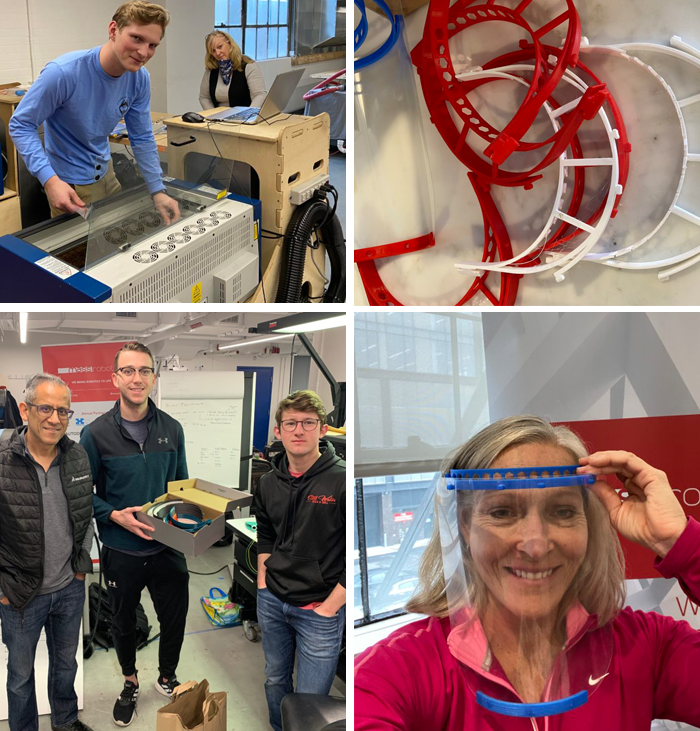

Two of our MassRobotics startup founders are taking a pause on their projects to mobilize ideas and resources to help solve shortages of critical PPE and medical equipment needed during this time of crisis. They are looking at the ventilator shortage and are designing a low-cost version but realized they could immediately make face shields. With the help of Dassault Systems and Autodesk, donating 3D printed headbands, to be assembled with our laser cut clear material, they made 100 shields and sent them to The Montefiord Medical Center in the Bronx, NY. The group is continuing to produce these shields to donate to Boston and local medical centers in need (see bottom of this post for more information to help).

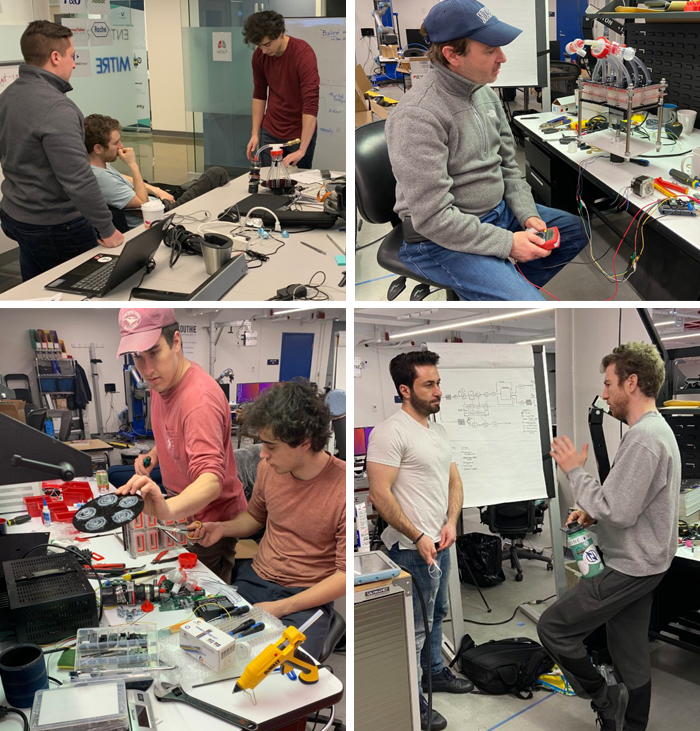

Alex Frost, Founder of FloraBot, and Tyler Mantel, Founder of Watertower Robotics, started The Ventilator Project, a non-profit looking to develop a low-cost ventilator specifically for COVID-19 patients. One ventilator typically costs about $40,000, according to estimates. This new nonprofit aims to rapidly prototype a ventilator that will cost between $1,000-$2,000.

The Ventilator Project was officially formed on March 20 – soon after Alex and Tyler spoke of the ventilator shortage, they dropped everything and worked to solve this problem. They’ve spoken to several medical professionals and come up with a design that uses non-traditional medical parts. Engineering expertise have come to support from all over the country and they’ve built a team of professionals and specialists including designers, supply chain & manufacturers, marketing & PR experts, and fundraisers to support the effort. Other startups at MassRobotics are also pitching in to support the effort including Cleo Robotics, Alias Robotics, TruPhysics, Mente, Hathaway Robitcs and Mente. Partners helping out include Solidworks, SMC, and MITRE. They are requesting additional support in several areas to include: controls and sensor integration engineers with experience in microelectronics, mechatronics and embedded systems, as well as a pneumatic engineer. If interested, please fill out this form.

Using the MassRobotics lab resources and Fab Foundation laser cutters they’ve iterated on their initial design several times. Working with FDA personnel, they hope to submit a design for approval in the upcoming weeks. There’s an article from the Robot Report here that offers additional information.

If you are interested in printing the 3D printed parts needed for the face shields you can download this STL file. Fill out the contact information sheet and let us know when you can drop off the donated prints in the lobby at our facility in Boston.