Written by Russell Nickerson, MassRobotics Engagement Liaison

RoboSource is an event aimed to get suppliers, manufacturers, service and solution providers in the hardware prototyping space to meet with aspiring startups, industry professionals and one another to share ways they can work together. The Venture Cafe at the Cambridge Innovation Center is a perfect location for networking in this manner. At MassRobotics we aim to put together a dynamic and highly impactful program in just an evening. Attendees listened to talks from Mark Smithers of Boston Engineering, Carl Palme from Boundless Robotics and Carsten Horn from maxon. These talks gave perspective and highlighted where there is overlap and opportunities between companies at any stage to work together and learn from each other.

We acknowledge the state of Massachusetts who is aligned with helping hardware manufacturers and startups by supporting initiatives to enable their success.

RoboSource highlights our Associated Network and partners that interact with startups in meaningful ways by providing a wide range of services and products. Boston Engineering, Newgrange Design, Cofactr, Ruland Manufacturing, CLA : CliftonLarsonAllen, Mascon, Camber Development, Igus and Inspiralia showed items from nano size 3d printing of components and boards to discussion of accounting services. A number of our larger partners understand the value of being involved with an event like RoboSource and also hosted tables.

They included Mitsubishi Electric, SOLIDWORKS, Danfoss (held in their old office at CIC!), maxon, Lattice Semiconductor and Nano Dimension. We like to think this event is better than a blind search engine roulette (the equivalent of closing your eyes flipping through the yellow pages of yore), attendees had the opportunity to speak with a variety of resources and get contacts in person from those who could be a resource for them in the near and distant future. The crowd at Venture Cafe’s are always bustling with a diverse range of students, seasoned professionals and even some investors. Events like these expose the beating pulse of the thriving Boston East Coast community, to which hardware is just one facet.

During my intro I mentioned the idea of an integrator. Everyone has a different thought on an integrator but typically the role takes over for tasks that the company is either not equipped to take on or just doesn’t want to do. The integrator role in itself can lead to many business opportunities for specialists and generalists. I like to think we are all integrators in some way. The definition of integrate is to combine something with another to make it whole. During the event, I asked people to think of different perspectives of others as integrators (even if they don’t call themselves that). Especially in the hardware field, we should all lean into each other’s unique skill sets to accomplish our goals and make the world work.

Thanks everyone for coming to RoboSource 2023 large or small, we hope you found someone there that could help your hardware endeavor come to fruition!

More information on the event below – contributed by Robotics247, Eugene Demaitre

CAMBRIDGE, Mass.—At last night’s RoboSource event, Venture Café and MassRobotics hosted discussions of how robotics developers, startups, investors, and users can collaborate to ensure they make the most of automation. RoboSource featured three speakers, 15 exhibitors, and over 400 attendees.

“The goal is to get people together from manufacturers, local startups, and large corporates,” said Russell Nickerson, engagement liaison at MassRobotics, in his introduction to the event. “It follows the concept of integrators, who help source materials and machinery and who provide engineers and sales expertise. Everyone in this community needs to help one another connect the dots and solve problems.”

MassRobotics provides co-working space, networking opportunities, and other resources to nurture the robotics ecosystem in Massachusetts. Venture Café Cambridge provides programming for innovators and entrepreneurs for the Boston area and beyond.

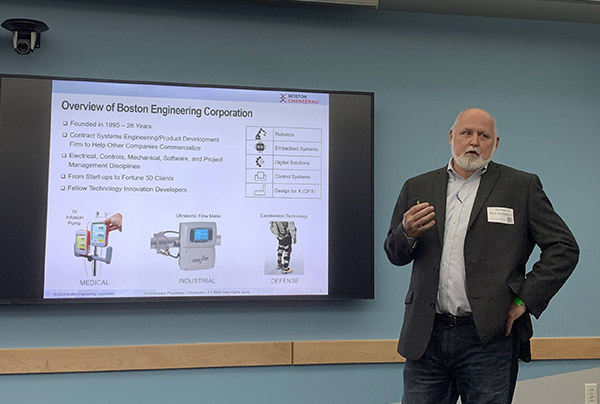

Boston Engineering shares insights into commercialization

The speakers at RoboSource represented a robotics integrator, a startup, and a component supplier.

Mark Smithers, chief technology officer at Boston Engineering Corp., explained that his company provides services to help companies commercialize their technologies. Waltham, Mass.-based Boston Engineeering has centers of excellence around robotics, embedded systems, digital solutions such as augmented reality (AR), controls, and “DFX” or design for manufacturing.

With more than 25 years of experience in working with innovators and federal Small Business Innovation Research (SBIR) grants, Boston Engineering has focused on overcoming hurdles to commercial viability, said Smithers. He outlined challenges at each of the following stages:

- Research: Technology may not be ready, and there are plenty of opportunities to fail, Smithers said. However, it’s OK to fail early, as long as risk is managed. “Researchers and entrepreneurs will push the limits of technology,” he said.

- Feasibility prototype: Sometimes, a technology is not convincing, which is why Boston Engineering focuses on DFX in taking products from “presentable” prototypes at Technology Readiness Level (TRL) 6 to commercialization at TRL 9.

- Alpha development: A common mistake is not understanding the users’ needs, Smithers noted. It’s important to think about them and ask during the design phase, he said.

- Beta development: Startups need resources to scale, and not just money, said Smithers. Organizations such as MassRobotics can help, he said.

- Production: Bringing an innovation into reality requires overcoming uncertainty. “Big business will pull when a technology is believable and commercially viable,” Smithers said. He also emphasized the importance of knowing desired production volumes and retaining control of one’s own manufacturing capabilities versus fully outsourcing them.

“You need people to help bridge the gaps between ideation and capitalization,” said Smithers. “Find subject-matter and DFX experts.”

Defining a product with potential customers early on can even lead to product redesign, he added. As with burning capital during design and development, robotics makers should have a sense of timing to steady-state production, Smithers said.

In addition, a modular design can help with future flexibility. Smithers cited the case of an underwater data-collection system that Boston Engineering developed for use by NOAA for hurricane forecasting, the U.S. Navy for mine countermeasures, and anti-submarine warfare.

Boston Engineering’s Mark Smithers described the company’s focus areas at RoboSource. Source: Eugene Demaitre

Boundless Robotics shows new autonomous growing system

Carl Palme, founder and CEO of MassRobotics resident startup Boundless Robotics Inc., had spent 10 years in manufacturing automation and wanted to grow food at home, but he didn’t have a green thumb. However, when he asked people about the idea of a robotic system for growing 5% of their own food, Palme found that there wasn’t enough demand.

The economics for pesticide-free, organic homegrown cannabis were different. The amount of money that consumers could save was compelling, but many of Palme’s male engineer friends felt they could build their own hydroponic systems.

Following Smithers’ point about listening to customers, Palme spoke with about 500 people over the course of three years and learned that women would be interested in a cannabis-growing system if it looked nice in a living room and if they could by it for their parents.

He said he redesigned Annaboto and sold 10 units in 2021. The final beta system shipped in summer 2022 with a new lamp, odor mitigation, and a camera capturing growth every 15 minutes so that people could track and share it with a smartphone app.

“You can’t treat hardware like software—it takes time, and you can’t magically push out upgrades. Making things that work repeatably is really hard,” Palme observed. “It’s more difficult to pivot, so you want to fail fast and not optimize too soon. You should fall in love with the problem, not the solution.”

He also recommended testing products in the field. “Nothing happens in the office,” said Palme. “You should also charge for beta tests so that early customers are invested in helping the product succeed.”

Boundless Robotics this week unveiled the production version of Annaboto, which will begin shipping next month.

Boundless Robotics’ Carl Palme shows production version of Annaboto at RoboSource. Source: Eugene Demaitre

maxon masters small motors

Taunton, Mass.-based maxon precision motors inc. has been providing drive systems for robotic applications since 1961, said Carsten Horn, application engineering manager at the U.S. unit of Switzerland-based maxon group.

Like Smithers and Palme, Horn pointed out that innovators and entrepreneurs should focus on design flexibility and understanding the target application and market.

He recalled that maxon’s current product line does not reflect the initial intent of principal shareholder Karl Walter Braun, who wanted to develop a small motor for an electric shaver. While that product didn’t succeed, the company successfully pivoted and now has more than 3,000 employees and ships 5 million battery-powered drives a year.

“We focus on smaller actuators used in robots, medical devices, and implants,” Horn said. “We also do systems integration and can help with some smaller systems development.”

Motors from maxon are also found in space exploration, exoskeletons, and prosthetics, he added. maxon expects some customization around its systems, and it maintains a global research and development organization, said Horn.

“Developers must understand that the technology has to solve a customer’s problem,” he concluded.

In addition to the speakers’ organizations, exhibitors at RoboSource included Camber Development, CliftonLarsonAllen, Cofactr, Danfoss, Dassault Systèmes SolidWorks, igus, Inspiralia Group, Lattice Semiconductor, Mascon, Mitsubishi Electric, Nano Dimension, Newgrange Design, and Ruland Manufacturing.

“We want each of our events to offer something different to help members of the Massachusetts robotics ecosystem,” Tom Ryden, executive director of MassRobotics, told Robotics 24/7.