On January 13, 2017 I was privileged be invited to the Pentagon to attend the U.S. Department of Defense’s announcement of the awarding of the 14th Manufacturing USA innovation institute for “Robots in Manufacturing Environments” to the Advanced Robotics Manufacturing (ARM) Institute. The ARM institute will receive $80 million from DOD, and an additional $173 million from the partner organizations.

ARM will be the center of a new wave of manufacturing, leveraging artificial intelligence, autonomy, 3-D printing and other emerging technologies to make industrial robotics more affordable for businesses of all sizes, adaptable for many uses, and able to achieve more. The ARM Institute has 220 partners in industry, academia, government, and the non-profit sector nationwide. MassRobotics is proud to be a partner of ARM and has been actively supporting the team by helping recruit additional members in our region and working closely with the State of Massachusetts to secure $5 million in matching funds.

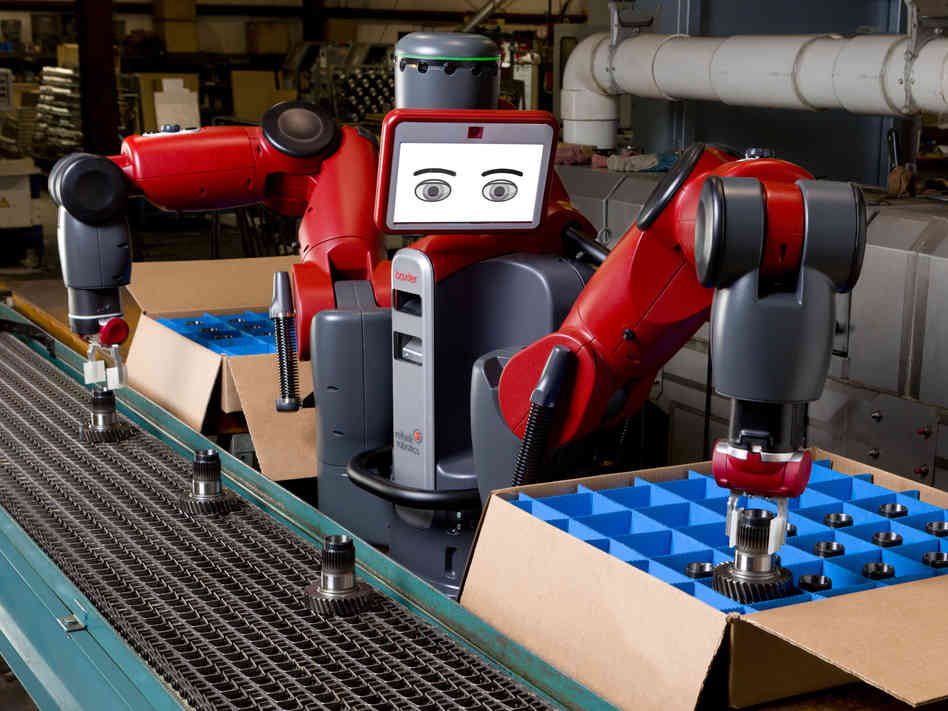

The use of robotics is already present in manufacturing environments, but today’s robots are typically expensive, singularly purposed, challenging to reprogram, and require isolation from humans for safety. Robotics are increasingly necessary to achieve the level of precision required for defense and other industrial manufacturing needs, but the capital cost and complexity of use often limits small to mid-size manufacturers from utilizing the technology.

The ARM Institute’s mission is to create and deploy robotic technology by integrating the diverse collection of industry practices and institutional knowledge across many disciplines – sensor technologies, end-effector development, software and artificial intelligence, materials science, human and machine behavior modeling, and quality assurance – to realize the promises of a robust manufacturing innovation ecosystem. Areas of technology development will include collaborative robotics, robot control (learning, adaptation, and repurposing), dexterous manipulation, autonomous navigation and mobility, perception and sensing, and testing, verification, and validation.

ARM joins the Manufacturing USA institute network, which is a bipartisan program that brings together industry, academia and government to co-invest in the development of world-leading manufacturing technologies and capabilities. Each Manufacturing USA institute focuses on a technology area critical to future competitiveness. In addition to robotics, other areas include 3D printing, integrated photonics or tissue fabrication. Across the Manufacturing USA institutes, the federal government has committed over $1 billion, which has been matched by over $2 billion in non-federal investment.

Tom Ryden, Executive Director, MassRobotics