The CHAMP (Chewy Autonomous Mobile Picking) Challenge, developed by Chewy in collaboration with MassRobotics, was created to address a persistent and technically complex limitation in warehouse automation: enabling fully autonomous robots to handle large, heavy, and non-rigid items within dense and dynamic fulfillment center environments. These items—often weighing over 40 pounds and exhibiting variable shapes, surface textures, and levels of deformability—present a multi-layered manipulation challenge. Their irregular geometry and low structural stiffness reduce the effectiveness of conventional suction or parallel-jaw gripping techniques, while inconsistent stacking and presentation on pallets further complicate object recognition and grasp planning.

Beyond the manipulation task, the CHAMP Challenge demanded system-level integration: robotic platforms needed to navigate through aisles as narrow as 20 inches, coordinate with live warehouse operations, and place picked items into shipping containers of varying dimensions, potentially with mixed-product contents. The challenge called for embodied AI solutions capable of perception-driven decision-making, robust grasp adaptation, and safe operation in collaborative settings. To support development, the Chewy Robotics team provided contestants with photos and videos of fulfillment operations, access to the Chewy robotics lab, and a comprehensive NVIDIA Omniverse simulation package, including a digital twin of the warehouse and 3D assets for a subset of Chewy’s product line. The challenge aimed to enable teams to validate their solutions, whether as simulation-based prototypes or as physical systems ready to interact with the real world.

Twelve global teams were selected to participate in the CHAMP Challenge, representing a diverse mix of early-stage startups and independent robotics engineers. Over several months, these teams engaged in close collaboration with members of the Chewy Robotics team who delivered guidance on operational constraints, fulfillment workflows, and system-level requirements. This hands-on mentorship enabled participants to refine their solutions beyond the lab, incorporating real-world logistics considerations into their autonomous robotic systems. The resulting prototypes combined hardware innovation with advanced perception, motion planning, and manipulation strategies tailored to the challenge’s demands. This collaborative effort not only advanced each team’s technical approach but also illuminated critical gaps in warehouse automation that remain unsolved, offering Chewy and the broader industry a clearer view of what’s needed to deploy robotics in high-throughput, constrained environments.

After a thorough evaluation, Chewy has named:

Winner: Black-I Robotics

Black-I Robotics, a Massachusetts-based MassRobotics resident with a strong foundation in defense-grade mobile manipulation, earned the $30,000 grand prize for delivering a sophisticated, full-stack autonomous picking system. Their solution featured a robust mobile base paired with a 6-DOF industrial arm, leveraging custom multi-modal end effectors engineered to handle large, deformable, and heavy SKUs.

Black-I’s approach integrated AI-driven perception with high-confidence object detection and pose estimation, enabling precise grasping of non-rigid items stacked on mixed pallets. The robot demonstrated full-facility navigation using fiducial markers and SLAM, dynamic obstacle avoidance for safe operation alongside warehouse associates, and seamless integration into downstream workflows via autonomous box placement.

Their consistent iteration, deep technical execution, and delivery of a complete mobile manipulation pipeline set their entry apart, meeting the challenge’s core demands for autonomy, adaptability, and deployability in constrained warehouse environments.

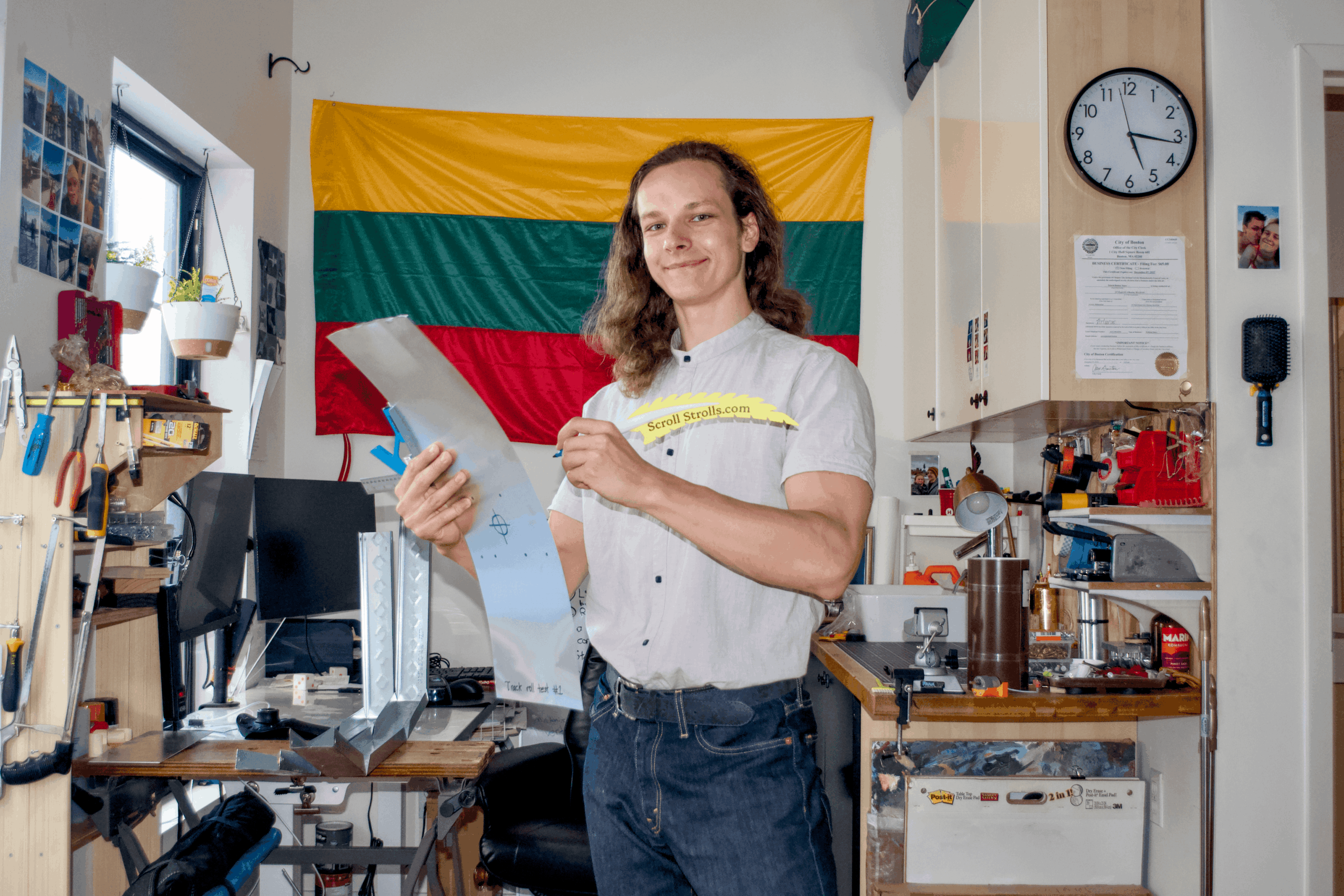

Runner-Up: Breezey Machine Company

Breezey Machine Company, a team of independent engineers from the Boston area, was awarded the $15,000 runner-up prize for their creative and mechanically elegant approach to one of warehouse automation’s most persistent challenges: handling large, heavy, and irregularly shaped packages in tight spaces.

Their solution focused on end-of-arm tool innovation, presenting a novel, low-profile gripper capable of adapting to deformable and variably stacked items with minimal pre-alignment. By emphasizing mechanical compliance and passive alignment strategies, Breezey’s design achieved secure grasps without relying heavily on high-precision vision or complex control algorithms.

The team also demonstrated thoughtful consideration of integration, proposing a modular arm-mounted system that could be retrofitted to existing mobile platforms or used within compact cell configurations. Their submission stood out for its practicality, manufacturability, and the potential to serve as a robust subsystem within larger automation workflows.

Breezey’s ingenuity and attention to real-world constraints exemplified the kind of targeted, systems-level thinking the CHAMP Challenge aimed to foster.